In industrial production, fluid control within pipeline systems is critically important. The pneumatic triple-offset butterfly valve, recognized for its innovative design and outstanding performance, has become a preferred solution across industries such as petroleum, chemical processing, metallurgy, power generation, food, pharmaceuticals, water supply and drainage, and gas transmission. This article provides a comprehensive introduction to the working principle, structural features, technical advantages, and application scenarios of pneumatic triple-offset butterfly valves, helping readers gain a complete understanding of this essential industrial control component.

A pneumatic triple-offset butterfly valve is a control unit composed of a pneumatic actuator and a triple-offset butterfly valve. Powered by compressed air, it receives the standard 4–20 mA signal output from industrial instruments and drives the valve stem to rotate the disc 0–90 degrees, enabling on/off control and flow regulation of pipeline media.

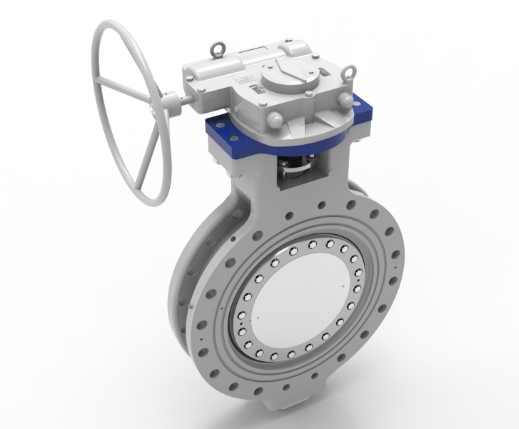

The term triple offset refers to three critical eccentric design features:

- First offset: The valve stem axis deviates from the pipeline center.

- Second offset: The valve stem axis deviates from the sealing surface center.

- Third offset: The sealing surface adopts a conical geometry.

The combination of these three offsets allows frictionless contact between sealing surfaces during opening and closing, significantly improving both service life and sealing performance.

After understanding the basic concept and application value of the pneumatic triple-offset butterfly valve, it is important to explore its internal construction and technical principles. These sophisticated structural designs enable the valve to maintain excellent performance under demanding operating conditions.

The triple-offset design represents the valve's primary technical advantage. Traditional butterfly valves generate sliding friction between the disc and seat during closure, leading to sealing surface wear and leakage. By contrast, the triple-offset valve employs a three-dimensional eccentric design that optimizes the spatial motion trajectory of the sealing surfaces.

When the valve closes, the eccentric disc advances forward, allowing the disc sealing surface to contact the seat directly without friction. This ensures that repeated operation does not damage the sealing surfaces.

In a typical triple-offset configuration, beyond the two offsets between the stem and disc, the sealing surfaces of both the disc and seat are shaped as inclined cones—forming the third offset. This geometry creates a uniform contact angle around the circumference, resembling a slender wedge. Meanwhile, the longitudinal sealing line along the disc perimeter forms a quasi-elliptical curve. Together, these features provide effective sealing compensation.

The pneumatic triple-offset butterfly valve utilizes a multi-layer metal sealing structure. The sealing ring is typically made of stainless steel, combining the strengths of hard metal sealing and elastic sealing. A boss structure is designed inside the sealing ring, leaving a small clearance between the boss and the elastic ring to allow slight displacement.

During valve closure, the elastic sealing ring automatically shifts to the position of most uniform stress under the closing force. Combined with slight deformation, this ensures evenly distributed pressure on the seat sealing ring and achieves optimal sealing. This self-compensating capability guarantees reliable sealing performance under varying conditions.

Users can select different sealing configurations based on operational needs, including:

- Integral soft seals (PTFE, C-TFE, G-TFE)

- Hardened metal sheet types

- Integral designs with hard alloys

The disc sealing surface is typically overlaid with cobalt-based or titanium-based hard alloys, offering exceptional wear resistance and significantly extending service life.

The pneumatic actuator serves as the valve's driving force and is available in two main types:

- Double-acting actuators: Require an air supply to move the valve in both directions.

- Single-acting actuators (spring return): Use a spring for reset, automatically returning the valve to a safe position if the air supply fails.

Two primary transmission methods are used:

- Rack-and-pinion drive: Features a dual-piston gear design with high output torque, compact size, and efficient structure.

- Scotch yoke drive: Commonly used in large-diameter valves, offering greater output force, structural rationality, and reliable operation.

The actuator cylinder is typically made of aluminum alloy, providing lightweight construction and an attractive appearance. Manual override mechanisms can be installed at both the top and bottom for operation during air supply failures. The rack-type connection design allows adjustment of the valve opening angle to control rated flow.

Having examined the technical principles behind the triple-offset structure, how does this frictionless, zero-leakage design perform in real-world operation? The following sections outline its core advantages from multiple dimensions, including sealing capability, operability, and adaptability.

The most prominent feature of the pneumatic triple-offset butterfly valve is its superior sealing capability. Thanks to the three-dimensional eccentric structure, the sealing surfaces separate instantly upon opening and seal immediately upon contact during closure, greatly reducing wear.

The valve supports bidirectional sealing, maintaining reliable performance regardless of flow direction. Sealing levels can reach zero-leakage standards, which is especially critical in applications with stringent sealing requirements. Whether operating under low or high temperatures, the combined hard metal and elastic sealing design ensures consistent performance.

Traditional butterfly valves must overcome friction between sealing surfaces during opening, resulting in high operating torque. In contrast, the triple-offset design allows all sealing points to disengage simultaneously from the seat without binding or friction, leading to extremely low opening torque.

This characteristic provides several benefits:

- More flexible and effortless operation

- Reduced energy consumption

- Smaller actuator sizes and lower equipment costs

- Decreased mechanical stress and improved system reliability

Pneumatic triple-offset butterfly valves are suitable for a broad range of media, including water, wastewater, seawater, air, steam, gas, combustible gases, corrosive media, oils, and food products. Selecting appropriate materials allows the valve to meet varying corrosion and temperature requirements.

Regarding temperature adaptability:

Soft-seated valves are typically used for lower temperatures.

Hard-seated valves can withstand temperatures up to 550°C–600°C, making them suitable for both low- and high-temperature conditions.

Because there is virtually no mechanical wear between sealing surfaces, and materials are carefully selected, pneumatic triple-offset butterfly valves offer extended service life. The seat and disc experience minimal wear during operation, and the sealing function tightens as the valve closes.

The disc sealing surface is overlaid with hard alloys for excellent wear resistance. Large-diameter discs often adopt truss or slotted structures that ensure sufficient strength while increasing flow area and reducing resistance. This design enables stable operation under high differential pressure and makes the valve resistant to high pressure, corrosion, and abrasion—representing a long-life, energy-efficient valve solution.

With bidirectional sealing capability, the valve is not restricted by flow direction or spatial orientation and can be installed in any direction. This flexibility simplifies pipeline design and on-site installation.

Actuators can be mounted in multiple positions (rotated 90° or 180°), allowing users to adapt layouts to site conditions. The valve uses an ISO5211 standard connection for easy installation and replacement. Adjustable screws at both ends provide a ±4° adjustment range at the 0° and 90° positions, ensuring synchronization accuracy with the valve.

After understanding the performance advantages of pneumatic triple-offset butterfly valves, selecting the most suitable product becomes crucial. Given the wide variation in operating conditions, these valves are available in multiple specifications based on connection type, sealing material, and body material. Scientific classification and proper selection are prerequisites for optimal performance and long-term stable operation.

Wafer-Type Pneumatic Triple-Offset Butterfly Valve: Features a thinner body installed between two flanges with bolts. Lightweight and space-saving, it is ideal for installations with limited space.

Flanged Pneumatic Triple-Offset Butterfly Valve: Equipped with flanges at both ends for direct pipeline connection. This method provides greater strength and reliability, making it suitable for high-pressure, large-diameter, or critical applications.

Soft-Sealed Type: Uses polymer materials such as PTFE. Offers excellent sealing but relatively lower temperature resistance, typically for conditions below 200°C.

Hard-Sealed Type: Employs stainless steel or hard alloys, withstanding temperatures up to 550–600°C and suitable for high-temperature, high-pressure, or particle-containing media.

Composite-Sealed Type: Combines the benefits of soft and hard seals to enhance both sealing performance and wear resistance.

Common materials include:

- WCB carbon steel: Suitable for general working conditions.

- 304 stainless steel: Appropriate for mildly corrosive media.

- 316 stainless steel: Ideal for more corrosive environments.

- Special alloy steels: Used in high-temperature, high-pressure, or strongly corrosive conditions.

When selecting a pneumatic triple-offset butterfly valve, consider the following factors:

- Media characteristics: Type, temperature, pressure, corrosiveness, and presence of solid particles—these determine body material and sealing form.

- Pipeline parameters: Nominal diameter (DN50–1200 mm) and nominal pressure (PN1.0–4.0 MPa). Large-diameter valves require AW-type actuators with higher output force.

- Control requirements: Determine whether simple on/off control or precise flow regulation is needed. Modulating applications require accessories such as positioners.

- Environmental conditions: Evaluate installation temperature, humidity, and explosion-proof requirements to select suitable pneumatic accessories.

- Petrochemical Industry: Widely used in pipelines transporting crude oil, refined products, chemical raw materials, intermediates, and finished products. Reliable sealing and corrosion resistance meet strict safety and environmental standards, while fast actuator response is crucial in high-temperature, high-pressure, and flammable conditions.

- Power Industry: Applied in boiler feedwater systems, steam systems, and cooling water circuits in thermal power plants, as well as specially designed nuclear-grade butterfly valves in nuclear facilities. The triple-offset structure meets the industry's high demands for reliability and longevity.

- Metallurgical Industry: Handles high-temperature gases, hot air, and flue gas during steelmaking processes. The valve withstands heat and dust erosion in critical systems such as blast furnace gas pipelines, hot blast stove systems, and dust removal units.

- Food and Pharmaceutical Industries: Strict hygiene requirements and often corrosive media demand stainless steel construction and food-grade sealing materials. These valves support CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes to ensure product safety and quality.

- Municipal Water Supply and Drainage: Large-diameter valves control flow and isolation in water supply networks, wastewater treatment plants, and seawater desalination projects. Bidirectional sealing simplifies installation, while low flow resistance reduces pumping energy consumption.

- Other Industrial Fields: Extensively used in paper, textile, shipbuilding, and HVAC industries. Their strong adaptability and ease of maintenance make them an excellent representative of general-purpose industrial valves.

With its distinctive triple-offset structure, outstanding sealing performance, broad applicability, and long service life, the pneumatic triple-offset butterfly valve occupies an important position in modern industrial pipeline control. Proper understanding of its working principles, rational selection, and standardized installation and maintenance can fully leverage the advantages of this high-performance valve, providing reliable assurance for safe, efficient, and energy-saving industrial operations. As technology continues to advance, pneumatic triple-offset butterfly valves will undoubtedly demonstrate exceptional value across an even wider range of applications.