In industries such as chemical processing, petroleum, and energy, failures of metal-seated ball valves used in solid particle conveying systems have long troubled engineers. Field data indicate that the typical online service life of these valves is only about six months; in extreme cases, severe failures can occur within two to three months. Internal leakage and sticking are the two most common failure modes. These issues not only result in frequent shutdowns and maintenance, increasing operational costs, but also become a critical bottleneck restricting the long-term stable operation of entire production units.

Why are ball valves so fragile under solid particle conditions? The answer lies in the unique characteristics of the process media. Unlike ordinary liquids or gases, solid particle media exhibit high hardness, poor flowability, a tendency to accumulate, and strong impact forces on sealing surfaces. When these particles pass through the metal seated ball valve at high velocity, they generate intense mechanical erosion and wear on the sealing pair. At the same time, complex physicochemical interactions, such as adhesion, corrosion, and oxidation, occur between sealing surfaces. The combined effect of these factors significantly accelerates valve failure.

- Erosion Failure of Sealing Surface Coatings: The moment a ball valve opens is when the sealing surface is most vulnerable. A large pressure differential exists between the upstream and downstream sides, while the flow passage is narrow, resulting in extremely high media velocity. Solid particles moving at such speeds act like sandpaper, aggressively eroding the coating of the sealing pair. With increased switching frequency, this erosion accumulates, gradually degrading the geometric accuracy and surface quality of the sealing face, ultimately causing severe internal leakage.

- Media Corrosion and Spalling: Beyond mechanical erosion, chemical corrosion and physical spalling caused by the process media are major contributors to leakage. Certain media are corrosive and react chemically with sealing materials, damaging their surface structure. Meanwhile, repeated particle impacts can cause localized spalling, forming pits or cracks that compromise the integrity of the sealing surface.

- Adhesion and Galling of the Sealing Pair: Research shows that adhesion can occur between the coating materials of metal-seated ball valve sealing pairs. If the coating materials are improperly selected, severe bonding may develop between sealing surfaces. During opening and closing, this adhesion can lead to galling, creating scratches or grooves that completely destroy sealing performance. This phenomenon is especially pronounced under high-temperature and high-pressure conditions, where intensified atomic activity makes material interpenetration and bonding more likely.

- Sealing Surface Galling: In operating sections with large pressure differentials and high temperatures, friction between sealing surfaces increases significantly. Much of the work required to overcome this friction converts into heat, further raising the sealing surface temperature and creating a vicious cycle. Elevated temperatures intensify adhesive and oxidative wear, and as switching cycles increase, galling becomes more likely, resulting in valve sticking.

- Solid Particle Accumulation: Solid particle media tend to flow poorly and settle easily. When the valve is closed, some particles may enter the valve cavity; during opening, they can accumulate and obstruct the normal rotation of the ball. This problem becomes more severe if critical components such as bearings and bushings are not hardened or are poorly designed, as particles can gather in these areas and cause sticking.

- Design Deficiencies in Bearings and Bushings: Traditional single-bearing designs often struggle under solid particle conditions. If bearings and bushings lack proper hardening, their surface hardness is insufficient to resist particle wear. Moreover, poorly designed structures allow particles to enter bearing clearances, increasing stem rotation resistance and potentially leading to seizure.

Understanding the mechanisms behind sealing surface damage is essential for effectively resolving ball valve failures. Based on root causes, damage can be categorized as follows:

The machining quality of sealing surfaces directly affects valve service life. Common defects include:

Cracks: Caused by improper welding overlay and heat treatment practices or poor workmanship.

Porosity and slag inclusions: Resulting from inadequate shielding or incorrect welding parameters.

Abnormal hardness: Either too high or too low due to improper material selection or heat treatment errors.

Uneven hardness: Occurs when base metal is blown onto the surface during overlay welding, diluting alloy composition.

Choosing valves without considering operating conditions is a frequent mistake. For example, using a shut-off valve for throttling leads to excessive sealing pressure. Closing too quickly or failing to close tightly subjects the sealing surface to excessive erosion and wear, significantly shortening its service life.

Incorrect installation can cause abnormal sealing surface behavior, forcing the valve to operate under faulty conditions. Lack of routine maintenance and failure to remove accumulated particles from the valve cavity further accelerate damage.

Media surrounding the sealing surface may react chemically with it, even without electrical current, causing corrosion. This type of damage is closely related to the chemical properties, temperature, and concentration of the medium.

When sealing surfaces contact each other, or interact with the closure member and valve body, potential differences may arise due to concentration gradients or oxygen differentials in the medium. Electrochemical corrosion follows, with the anodic surface corroding first.

Flowing media can wear, scour, and cavitate sealing surfaces:

Fine particle impact: Suspended particles strike the sealing face at speed, causing localized damage.

High-velocity scouring: Rapid flow directly erodes the surface.

Cavitation: Mixed flow and localized vaporization produce bubble collapse that impacts the sealing surface.

Alternating erosion and chemical corrosion can aggressively degrade sealing surfaces and accelerate failure.

During opening and closing, sealing surfaces may suffer scratches, impacts, and crushing. Under high temperature and pressure, atomic interpenetration between surfaces can lead to adhesion. When movement occurs, bonded areas may tear apart, an effect that worsens with higher surface roughness.

Over long-term use, cyclic loads generate fatigue, leading to cracks and delamination. Rubber and plastic sealing components may also age, reducing performance.

Addressing these challenges requires systematic optimization of the valve's overall structure. The following measures have proven effective in practice:

Selecting coating materials is a systems engineering task. Higher hardness does not necessarily mean better performance, and no “universal material” exists. Instead, suitable hard alloy coatings should be chosen based on process conditions and operational requirements.

Through extensive ratio testing, specialized hard alloy coatings with exceptional application-specific performance have been identified. Ideal materials should offer:

- Anti-adhesion properties to prevent bonding between sealing surfaces

- Oxidation resistance to withstand high temperatures

- Good thermal conductivity to dissipate heat and avoid buildup

- Electrical conductivity to prevent electrostatic discharge

Such coatings effectively resolve challenges related to adhesion, oxidation, heat accumulation, and static discharge in high-pressure, high-temperature, and clean gas applications, while significantly improving wear resistance and service life in solid particle environments.

Adopting a dual-bearing design with hardened bushings provides two key advantages:

- Additional rotation support points, improving load distribution

- Enhanced wear resistance and strength through materials of varying hardness

This design ensures that even under long-term, high-frequency operation, no galling occurs between the valve stem, bearings, and bushings, fundamentally eliminating sticking issues.

Disc springs are increasingly used as elastic compensation elements in solid particle ball valves. Traditional disc springs, however, produce fluctuating torque during operation, even under zero pressure.

The fluctuation arises because the seat tilts during closure, causing different preload forces at the starting and closing positions. Slotted disc springs solve this problem through a unique opening design:

During opening or closing, the slot reduces force on the slotted side. Although seat tilt increases compression on one side, the slot balances the forces. As a result, friction torque between the ball and seat coating remains nearly constant, lowering operating torque and effectively preventing sticking.

Although material entering disc spring areas is easier to discharge than in coil springs, particles can still accumulate in the triangular space formed between the spring and the valve body or bonnet. Pressure fluctuations cause slight seat displacement, and deformation gaps may fill with solids or slurry, preventing the spring from resetting and eliminating its elastic compensation function.

A dust relief groove effectively resolves this issue by allowing ash or slurry behind the disc spring to be discharged promptly. This maintains seat flexibility, keeps torque within design limits, and ensures normal system operation.

Designing the seat edge with a sharp profile allows it to function like a scraper. As the ball rotates, the sharp edge removes particles adhering to the ball surface, preventing them from entering the gap between the seat and the ball and reducing sticking risk.

Surface roughness and dimensional tolerances between the seat ring and the seat pocket must be carefully controlled to:

- Prevent extrusion of graphite sealing materials within specified temperature ranges

- Avoid seat bonding caused by thermal expansion

- Ensure support components do not tilt during operation

The seat surface should possess sufficient hardness and be free from stains, cracks, or dents. Strict quality control ensures geometric precision and surface integrity, laying the foundation for long-term stable operation.

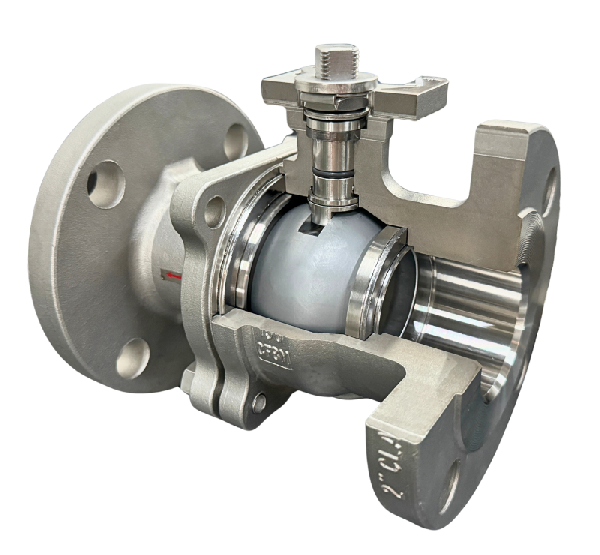

Optimized metal-seated ball valves demonstrate outstanding performance in solid particle applications. By preventing impurities within the valve cavity from entering the space between the valve body and seat, issues such as internal leakage, sticking, and incomplete operation are effectively resolved.

These high-performance valves offer:

- Extended service life with significantly improved sealing durability

- High-temperature resistance for demanding operating conditions

- Superior wear resistance against mechanical abrasion from particles

- Excellent erosion resistance under high-velocity flow

Today, these valves are widely used in petrochemical solid product discharge pipelines as well as in high-temperature, high-pressure, corrosive, crystallizing, and sediment-laden media conditions. Their strong performance has earned broad recognition across the industry.

Failures of metal-seated ball valves under solid particle conditions represent a complex systems engineering challenge involving materials science, mechanical design, manufacturing processes, and maintenance practices. To address these issues comprehensively, the following strategies are recommended:

- Scientific material selection: Choose sealing materials based on actual operating conditions rather than blindly pursuing higher hardness.

- Structural optimization: Implement advanced designs such as dual bearings, slotted disc springs, and dust relief grooves.

- Precision manufacturing: Strictly control machining quality to prevent defects such as cracks and porosity.

- Proper valve selection: Match valve type and specifications to process requirements.

- Standardized installation: Ensure installation accuracy to avoid additional stresses.

- Regular maintenance: Establish a robust maintenance program and promptly remove accumulated materials.

With systematic design optimization and scientific operation and maintenance management, the online service life of ball valves in solid particle applications can be extended from just a few months to several years. This significantly enhances operational reliability, reduces lifecycle costs, and creates greater economic value for enterprises.