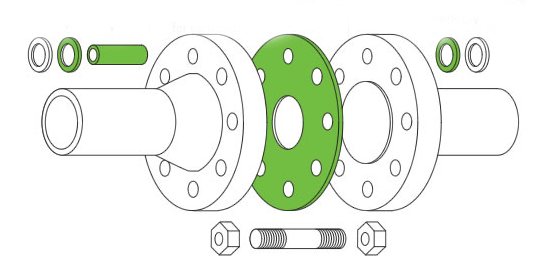

In the industrial field, flange connections are an extremely common method of connection, widely used in numerous scenarios such as pipelines, valves, and equipment. It achieves sealing through the coordinated action of bolts, flanges, and gaskets, ensuring the safe transmission of fluids in pipeline systems. Today, let's delve into the sealing principles, influencing factors, and maintenance tips of flange connections to help everyone better understand and apply this important engineering technology.

The core of flange connections lies in sealing, which is mainly achieved through the coordinated action of bolts, flanges, and gaskets. The gasket is the key component for sealing. Through the pre-tension force of the bolts, sufficient pressure is generated between the gasket and the flange sealing surface, causing the gasket surface to deform and fill the micro-irregularities of the flange sealing surface, thereby achieving sealing.

To achieve sealing, the gasket needs to withstand a certain clamping force. The minimum unit of this clamping force is called the specific pressure. When the pipeline reaches the operating pressure, due to the axial force of the internal pressure, the flange tends to separate, and the bolts tend to elongate, resulting in a reduction in the clamping force acting on the gasket. When the clamping force drops to a certain critical value, the gasket can still maintain sealing. This critical value is the effective clamping force of the gasket. If the clamping force on the gasket is less than the effective clamping force, the flange will leak, and the gasket may even be blown away. Therefore, the effective clamping force of the gasket must be greater than the operating pressure of the pipeline.

During operation, the distance between the flange sealing surfaces will be greater than the initial state. At this time, the tightness between the gasket and the flange sealing surface mainly relies on the resilience of the gasket to ensure. In the initial sealing stage, the surface plastic deformation of the gasket plays a decisive role; while in the operating state, the elastic recovery inside the gasket plays a dominant role.

Flange connections are indispensable components in engineering design and are widely used in piping design, pipe fittings, valves, and equipment components. Depending on different application scenarios and requirements, there are various types of flange connections, each with its unique characteristics and applicable scope.

The flat face flange has a simple structure and is easy to process. However, it has a large contact area, requires a high pre-tension specific pressure, and the bolts bear a large load. Therefore, the flange and other parts are required to be of high quality and heavy. The gasket is prone to extrusion, and the sealing performance is relatively poor. The operating pressure is generally not more than 2.5 MPa, and it is not suitable for toxic, flammable, and explosive media.

The raised face flange is easy to align, can prevent gasket extrusion, and is less susceptible to erosion and corrosion by the medium. It is suitable for high-pressure applications. However, this type of flange is not convenient for gasket replacement.

The tongue and groove flange is composed of a tongue surface and a groove surface. The gasket is placed in the groove and will not be extruded out of the clamping surface, and it is less affected by the erosion and corrosion of the medium. Due to the narrow sealing surface, the required bolt force is smaller. It is suitable for higher pressure and stricter sealing requirements, such as in important occasions with flammable, explosive, and highly or extremely toxic media. However, its structure is complex, the gasket is easily squeezed into the groove and difficult to remove, and gasket replacement is more challenging. In addition, the tongue surface flange needs to be protected during transportation to avoid collision deformation.

The ring joint flange is mainly used on necked butt-weld flanges and integral flanges. It has good sealing performance and general installation requirements, and is suitable for high-temperature and high-pressure conditions. However, the machining accuracy of the sealing surface is extremely high.

The leakage of flange sealing is mainly due to the leakage between the sealing surfaces, and the possibility of leakage due to the capillary action of the gasket is very small. After the gasket is pressed by external force, it fills the tiny uneven gaps on the sealing surface through its own elastic and plastic deformation. When the resistance of the medium passing through the sealing surface is greater than the pressure difference on both sides of the sealing surface, sealing is achieved. However, when affected by external conditions, the seal may be compromised, resulting in leakage. The main factors affecting sealing are as follows.

Operating conditions include pressure, temperature, and the physicochemical properties of the medium. In petrochemical plants, low-pressure flanges are more common, and the influence of pressure or medium factors alone on flange leakage is not significant. Only when temperature and pressure act together does the problem become serious. In particular, when the temperature changes repeatedly, the possibility of seal failure is greater.

Even for the same material, the gasket factor and specific pressure are also related to factors such as gasket width, pre-tension pressure, medium properties, flange sealing surface width, and roughness. There is currently no authoritative standard for selection, so adjustments need to be made according to specific conditions in practical applications.

Increasing the bolt pre-tension force can enhance the sealing performance of the gasket. However, excessive bolt pre-tension force can cause the gasket to lose elasticity, or even crush the gasket or damage the flange sealing surface, failing to ensure sufficient elasticity in the working state.

The gasket material is the main factor affecting the performance of the gasket, so the quality of the gasket will directly affect the sealing of the flange. The deformation of the gasket includes elastic and plastic deformation, and selecting the appropriate gasket material is crucial for ensuring sealing performance.

Insufficient flange stiffness can cause excessive warping deformation, which is often one of the reasons for seal failure. The shape and roughness of the flange sealing surface should be compatible with the gasket. The flatness of the sealing surface and the perpendicularity of the sealing surface to the flange axis are prerequisites for ensuring the uniform clamping of the gasket. During design and installation, the thrust or eccentric force caused by pipeline thermal expansion must be considered, otherwise, it is easy to cause flange seal failure and leakage.

Flange leakage generally occurs through two paths: the first is the permeation of the gasket itself, and the second is the leakage through the gap between the gasket and the flange sealing surface. With the continuous emergence of new sealing materials, the first type of leakage has been basically resolved, and the vast majority of daily occurrences are the second type of leakage.

Under specific operating conditions, if the leakage rate that a flange connection can achieve is lower than a specific indicator leakage rate, or if the flange connection can withstand specific operating conditions under specified leakage conditions, the flange connection is considered not to leak or to be tight. Conversely, it is considered to leak or to be not tight.

The force conditions of flanges in actual working conditions are very complex. Bolts, gaskets, and internal pressure all directly exert forces on the flange, which may cause irregular deformation of the flange. From a strength perspective, these forces are not a problem, but deformation may lead to flange leakage. Therefore, in flange design, it is necessary to meet not only the strength requirements but also the minimum deformation required for flange non-leakage, that is, design according to the stiffness theory.

Tightening bolts can improve sealing effectiveness and reduce leakage rates. However, due to the limitations of the strength and stiffness of the flange and bolts themselves, this method becomes ineffective after a certain point. Improper bolt installation procedures can also cause leakage. The correct bolt tightening sequence (such as crosswise equidistant symmetry) is extremely important for ensuring the sealing of flange connections and reducing tightening operation time.

To ensure the sealing performance and service life of flange connections, regular maintenance and inspection are essential. Here are some key points for maintenance and inspection:

Due to factors such as temperature changes and vibration, the tightening force of bolts may change. Regularly inspecting the tightening condition of bolts to ensure they reach the designed pre-tension force is an important measure to prevent flange leakage.

Gaskets may wear or age during long-term use, leading to a decline in sealing performance. Regularly inspecting the wear condition of gaskets and promptly replacing damaged ones can effectively prevent leakage.

The flatness and cleanliness of the flange sealing surface directly affect the sealing effect. Regularly inspecting the flange sealing surface, removing surface dirt and debris, and ensuring the flatness and cleanliness of the sealing surface is crucial for maintaining sealing performance.

Flanges may deform during long-term use, affecting sealing performance. Regularly inspecting the deformation condition of flanges and addressing any issues promptly can effectively prevent leakage.

Changes in operating conditions, such as pressure, temperature, and medium composition, may affect flange sealing. Regularly inspecting changes in operating conditions and adjusting the sealing measures of flange connections in a timely manner can effectively prevent leakage.

As an important industrial connection method, flange connections play a vital role in pipeline systems. They achieve sealing through the coordinated action of bolts, flanges, and gaskets, ensuring the safe transmission of fluids. Understanding the sealing principles, influencing factors, and maintenance tips of flange connections is of great significance for improving their sealing performance and service life. In practical applications, we need to select the appropriate flange type, gasket material, and bolt pre-tension force based on specific operating conditions and requirements. Regular maintenance and inspection should also be carried out to ensure the safe and reliable operation of flange connections. Only in this way can we ensure the stable operation of pipeline systems in complex industrial environments and prevent safety accidents and economic losses caused by flange leakage.