In industrial applications, the sealing performance of mechanical equipment is critical. It directly affects operational efficiency, safety, and the service life of machines. Among the various sealing methods, packing seals, a type of contact seal, are widely used due to their simple structure, relatively low cost, and ease of maintenance. However, packing seals inevitably face challenges, with friction and wear being the most prominent. This article explores the principles of friction and lubrication in packing seals, the factors that affect their performance, and how proper selection of lubricants and optimized design can enhance sealing effectiveness and prolong service life.

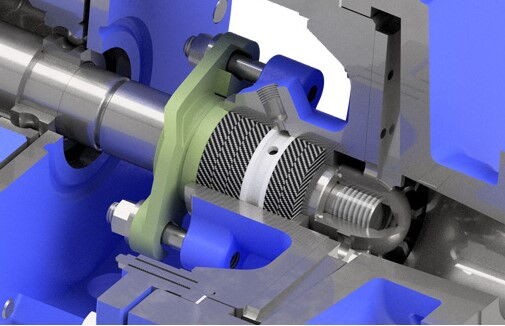

Packing seals operate by filling a sealing cavity with packing material, which is then compressed against a shaft or valve stem using a gland. The seal is achieved by the elastic and plastic deformation of the packing material, which fills gaps in the cavity and prevents leakage of the working medium. Compared to other sealing methods, packing seals have a larger contact area and require applied compressive force, making them particularly susceptible to friction and wear during operation.

The effectiveness of a packing seal depends on several factors: the material of the packing, its structure, the applied compressive force, and the surface condition of the shaft or valve stem. Packing materials vary widely and include cotton, hemp, asbestos, carbon fiber, and polytetrafluoroethylene (PTFE). Each material has distinct physical and chemical properties that influence its sealing performance and longevity. For example, the friction coefficient of PTFE against steel is only 0.04, while cotton against steel ranges between 0.6 and 0.7—a difference of nearly 20 times. This demonstrates the significant role material selection plays in friction, wear, and ultimately, sealing effectiveness.

Understanding the principles of packing seals leads naturally to an examination of the two major practical challenges: friction and wear. These issues directly influence the seal's performance and durability and must be addressed in design, material selection, and maintenance.

Several factors affect the friction of a packing seal, including gland pressure, operating time, the number of packing rings, shaft surface roughness, and the type of packing material.

- Gland Pressure: Gland pressure is a critical parameter. Proper pressure ensures tight contact between the packing and the shaft, achieving effective sealing. Excessive pressure, however, over-compresses the packing, generating heat, accelerating aging and wear, and potentially deforming the shaft or valve stem. Insufficient pressure leads to leakage. Therefore, precise control of gland pressure is essential for optimal performance.

- Operating Time: Over time, friction causes the packing material to wear, with the surface becoming rough, cracked, or damaged, thereby reducing sealing performance. Regular inspection and replacement of packing material are necessary to maintain reliable operation.

- Number of Packing Rings: Fewer packing rings reduce the frictional contact area, decreasing heat generation, but may compromise sealing. Conversely, more rings improve sealing but increase friction and wear. A balance must be struck between friction reduction and sealing effectiveness.

- Shaft Surface Roughness: A rough shaft surface increases friction and wear. Smoother surfaces minimize friction and extend packing life. Surface preparation and finishing are therefore crucial.

- Type of Packing Material: Different packing materials have widely varying friction coefficients and wear resistance. Carbon fiber has superior wear resistance, while asbestos causes significant wear on shafts—up to 50 times greater. Impregnation with PTFE or other agents can improve wear resistance dramatically, demonstrating the importance of chemical treatment and filler materials.

Wear is a central concern in packing seals, and spare parts are commonly stocked in equipment using such seals. Wear can manifest in several forms:

- Uniform Wear: Properly installed packing wears evenly, with greater wear near the gland and decreasing inward. This is typical during normal operation and can be managed by routine inspection and replacement.

- Localized Wear: Improper installation or uneven gland pressure can cause severe wear in specific areas while leaving other parts intact. Localized wear compromises the seal structure and increases the risk of leakage.

- Corrosive Wear: When stainless steel shafts are used with graphite-packed seals, electrochemical corrosion may occur. Graphite acts as a cathode in conductive media, while the steel shaft becomes the anode, dissolving metal and creating rough surfaces, which accelerates wear. To prevent this, sacrificial metals like copper, aluminum, zinc, or magnesium can be intentionally included in the packing to protect the shaft through controlled electrochemical interactions.

Lubricants play a vital role in packing seals. Leakage often results from improper or insufficient lubrication. Lubricants reduce friction between the packing and shaft, dissipate heat, stabilize the seal temperature, and extend the life of both the packing and equipment.

Selecting an appropriate lubricant requires consideration of operating conditions, speed, load, temperature, environmental humidity, and corrosive atmosphere.

- Operating Conditions: High-temperature applications require lubricants with high thermal stability to prevent evaporation and dry friction, which can destroy the packing. Low-temperature applications require low-viscosity lubricants to ensure proper penetration. Chemical compatibility must also be considered to avoid hazardous reactions.

- Movement Speed: Higher speeds demand lubricants with strong penetrability and lower viscosity. High-viscosity oils or greases at high speed increase friction and heat. At low speeds, higher viscosity lubricants may be needed to support load.

- Load: Heavier loads require higher viscosity lubricants to maintain a lubricating film. In shock or intermittent movements, solid lubricants or high-viscosity greases are recommended for reliable performance.

- Operating Temperature: Lubricant selection should exceed the working temperature by 20–30°C to account for heat generation from friction. Solid lubricants may be required above 200°C.

- Humidity: Moist environments risk lubricant washout or degradation. Lubricants with water resistance, such as greases, are preferred.

- Corrosive Atmosphere: Lubricants with good corrosion resistance can protect metals by forming a barrier against corrosive gases or liquids.

Several lubricants are widely used for packing seals:

- Animal Fats: Suitable for cold water and fiber packings but may decompose in corrosive media.

- Castor Oil: Suitable for water and acidic salts, but can dissolve petroleum-based oils.

- Palm Wax: Water-resistant and compatible with castor oil, suitable for humid environments.

- Glycerin: Ideal for petroleum products and steam, with good water resistance.

- Mineral Oil or Paraffin: Best for moderate temperature applications, e.g., cylinder packing.

- Graphite: Excellent solid lubricant with stable chemistry; however, its conductivity may cause electrochemical corrosion.

- Molybdenum Disulfide (MoS₂): Effective for high pressure-velocity (PV) conditions, non-conductive, temperature limit ~300°C.

- Mica and Talc: High-temperature, non-graphite applications; slightly higher friction.

- PTFE: Serves as both filler and lubricant, operates from -200°C to 250°C, chemically resistant, non-conductive.

Enhancing the performance and lifespan of packing seals requires both design optimization and proper maintenance.

- Material and Structure Selection: Choose packing material based on operating conditions, such as carbon fiber or PTFE for high temperature, high pressure, or corrosive environments.

- Gland Design: Ensure uniform pressure distribution, possibly using spring-loaded or hydraulic glands to maintain consistent contact.

- Cooling: In high-temperature applications, introduce cooling devices like water jackets or air cooling to reduce heat accumulation.

- Composite Packing: Combine different materials, e.g., carbon fiber with PTFE, to maximize wear resistance and reduce friction.

- Regular Inspection: Check wear, seal integrity, gland pressure, and lubricant status.

- Timely Replacement: Replace worn packing promptly, ensuring even and tight installation.

- Lubricant Replenishment: Maintain sufficient and compatible lubrication.

- Equipment Care: Routine cleaning, lubrication, and inspection reduce wear and extend the lifespan of both packing and machinery.

A chemical plant's centrifugal pump experienced frequent packing leaks. Investigation revealed severe wear and dried lubricant. The root causes were:

- Improper packing material: Ordinary asbestos with poor wear resistance and poor high-temperature performance.

- Unsuitable lubricant: Mineral oil, volatile at high temperatures, causing dry friction.

- Incorrect gland pressure: Insufficient contact pressure between packing and shaft.

Improvements included:

- Replacing asbestos with carbon fiber packing for better wear and temperature resistance.

- Using high-temperature PTFE lubricant for stable lubrication.

- Adjusting gland pressure for even and sufficient compression.

- Post-improvement, leakage was eliminated, packing performance improved, and pump operation stabilized.

Packing seals are widely used contact seals in industrial machinery, but friction and wear remain primary factors limiting their performance and service life. By understanding the mechanisms of friction and wear, selecting suitable lubricants, and implementing optimized design and maintenance strategies, the operational efficiency, sealing effectiveness, and lifespan of packing seals can be significantly improved. In practice, careful consideration of the working environment, material selection, lubrication, and structural optimization ensures long-term, reliable equipment operation.