In the industrial field, valves, as key equipment for controlling fluid flow, have sealing performance that is of utmost importance. The fugitive emission control performance of valves directly affects production safety, environmental protection, and production efficiency. With the continuous global increase in environmental protection and safety requirements, testing and certification of valve fugitive emission control performance have become increasingly important. This article will provide a detailed introduction to the main international standards for valve fugitive emission control performance testing and certification, including Europe's ISO 15848-1, the United States'API 624, and Germany's VDI 2440 certification, and explore how these standards ensure valves achieve low fugitive emission performance.

- ISO 15848-1 (Europe): ISO 15848-1 is the leading recognized testing standard in Europe, used to evaluate external leakage of valve stem seals (or shafts) and valve body joints in isolation and control valves handling volatile air pollutants and hazardous fluids. This standard defines a classification system and identification procedure for valve type testing and divides sealing performance into three levels: A, B, and C, with Level A having the lowest environmental leakage. ISO 15848-1:2005 does not cover end connections, vacuum applications, corrosion, or radiation effects. Through rigorous testing, this standard ensures that valves maintain good sealing performance under various operating conditions, effectively preventing leakage of harmful gases and liquids, and protecting both the environment and personnel safety.

- API 624 (United States): In the United States, API 624 is the main standard for valve fugitive emission control performance testing and certification. API 624 clearly defines the requirements and acceptance criteria (100 ppmv) for low-leakage type testing of rising stem and rotary valves with graphite packing. This standard requires packing to be suitable for use at temperatures ranging from -29°C to 538°C (–20°F to 1000°F), and the test medium must be methane with 97% purity. The testing process includes 310 mechanical cycles and 3 thermal cycle periods, beginning with mechanical cycling at room temperature, with optional low-temperature testing at -29°C (-20°F) if requested by the purchaser. The heating temperature should rise to 260°C (500°F) ±5%, and the test pressure should remain below 41.1 bar (600 PSI), or follow the maximum allowable pressure at 260°C (500°F) according to ASME B16.34, and remain constant throughout the test. API 624 provides clear testing methods and acceptance criteria for valve manufacturers and users, ensuring low-leakage performance in practical applications and reducing environmental pollution risk.

- VDI 2440 Certification (Germany): Germany's VDI 2440 certification is specifically aimed at valves used in the chemical and petrochemical industries. In Germany, all valves applied in chemical and petrochemical industries must obtain VDI 2440 certification to ensure safety and reliability when handling hazardous chemicals and flammable or explosive materials. VDI 2440 certification imposes strict requirements on sealing performance, material selection, and structural design of valves. Through a series of tests and evaluations, it ensures that valves maintain good sealing performance under complex operating conditions, preventing leakage of harmful substances and ensuring safe production in the chemical and petrochemical industries.

- Stem Packing Seals: Stem packing seals are the most critical components for controlling valve fugitive emissions, as they are the only sealing surface in dynamic contact, and lie between the high-pressure internal environment and the ambient external atmosphere. There are many different stem seal structures that can achieve low fugitive emission control, with packing being the most common method. Packing can be made of expanded graphite with reinforced fibers, or PTFE woven or molded. Expanded graphite packing performs excellently under high-temperature conditions. Pure graphite is an excellent sealing material for large molecules, such as water, making it ideal for steam applications. However, for sealing hydrocarbon media and gases such as helium, pure graphite structures must be reinforced with other materials. PTFE packing has good sealing performance, but only at low temperatures, up to a maximum of 260°C, which also limits its use in conditions requiring fire resistance.

- Spring-Energized Seals: Spring-energized seals are another common stem seal structure. These seals achieve sealing through spring tension at low pressure and internal system pressure at high pressure. Various polymer materials, such as PTFE, can be used as options. Backup rings are sometimes needed to enhance reliability and high-pressure capability. The springs used are typically made of corrosion-resistant materials to ensure reliability under extreme conditions. In ultra-low temperature applications, spring-energized seals often use special materials for the jacket and springs, because conventional packing is generally not suitable.

- Metal Bellows Seals: Some valves use metal bellows to achieve sealing. Failure of this type of seal can cause catastrophic leakage, so secondary packing seals are often necessary. Metal bellows seals have excellent sealing performance and high-pressure resistance, suitable for applications with extremely high sealing requirements, but their design and manufacturing require special attention to ensure reliability and safety.

- Use High-Quality, Reliable Stem Seals: Selecting high-quality, reliable stem seals is the foundation for ensuring low fugitive emission performance. Low-emission packing typically contains special fillers and barriers, making it dense and impervious to water, and even preventing escape of the smallest molecules, such as helium. When selecting stem seals, it is necessary to choose appropriate sealing materials and structures based on the valve's actual operating conditions and requirements, ensuring reliable sealing under all conditions.

- Valve Condition Must Be Suitable for Sealing: Valve condition also has an important impact on sealing performance. The sealing stress of the stem packing is directly formed by the gland and follower. This force is transmitted to the packing, creating radial pressure. This radial pressure causes packing deformation and sealing, and also generates friction on the valve stem. The higher the gland force, the higher the sealing stress and the lower the leakage. Therefore, to achieve effective performance of low-emission packing, relatively high sealing stress must be applied to the packing. Conventional valves often lack the structural strength to meet these requirements, so improvements in packing box configuration, such as hinge bolts and gland upgrades, are usually necessary; for example, upgrading to hinge bolts with higher yield strength. In addition, the stem surface roughness is a key factor in meeting low fugitive emission requirements. Excessive or insufficient roughness can cause graphite packing to be dislodged. Therefore, roughness must be adjusted. Too low a stem roughness can lead to graphite sticking and slipping issues.

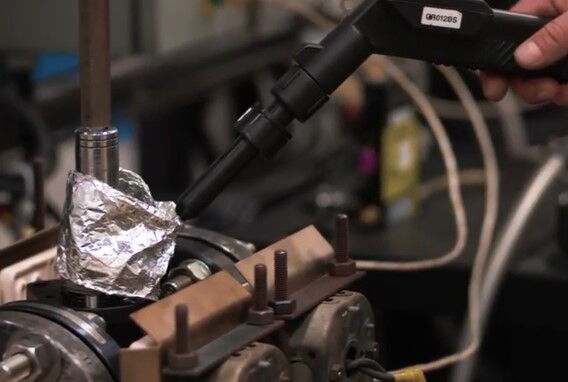

- Proper Installation of Valve Seals: Proper installation is crucial for low-emission control. The installation process of packing in a laboratory environment may differ from on-site replacement or from the manufacturer's procedure. Correct installation steps are essential, especially for low-emission control valves. Special attention is required to ensure the packing is not damaged during installation, and that each ring of packing receives sufficient sealing stress for effective sealing. Achieving the desired result may require repeated trials and adjustments.

Low-leakage type testing is a key step in ensuring valve sealing performance. Different regional standards have different focuses. The following introduces the specific requirements and implementation details of API 624 and ISO 15848-1 standards.

API 624 defines low-leakage type testing requirements and acceptance criteria (100 ppmv) for rising stem and rotary valves with graphite packing. The test includes 310 mechanical cycles and 3 thermal cycles, starting at room temperature, with optional -29°C (-20°F) low-temperature testing. Heating must reach 260°C (500°F) ±5%, test pressure below 41.1 bar (600 PSI) or per ASME B16.34 maximum allowable pressure, and remain constant. The test medium is 97% pure methane, with safety measures in place. The valve stem must be vertical. Test reports must include API 622 certificates or test reports for the packing.

ISO 15848-1 defines a classification system and identification procedure for valve type testing, assessing external leakage of stem seals in valves handling volatile air pollutants and hazardous fluids. The standard consists of two parts:

- Classification System and Identification Procedure: Three sealing levels: A, B, C, with Level A having the lowest leakage.

- Production Acceptance Testing: Helium leak detection without mechanical influence. Tests include:

- Leakage Test: Detect and record leakage from the sealing surfaces to determine compliance.

- Gland Force Test: Measure packing compression and stem tightening force to ensure sealing.

- Seepage Test: Introduce water, detect leakage paths, and record leakage.

After testing, acceptance is determined based on performance and leakage rate, including leakage, stem position, seepage, and packing sealing inspection.

- Select Appropriate Stem Seals: Choosing the right stem seal according to operating conditions is critical. Low-emission packing contains special fillers and barriers, making it dense and impervious to helium. Graphite packing is used at high temperatures, while spring-energized seals with special materials are used at low temperatures. Packing selection must consider temperature range, chemical compatibility, and mechanical performance to ensure sealing.

- Optimize Valve Design: Simply selecting low-emission packing is not enough; valve design must also be optimized. Sealing stress is generated by the gland and follower, transmitted to the packing, creating radial pressure and stem friction. Sealing stress must be increased, which may require upgrading packing box configuration and materials. Packing gaps must be minimized to prevent extrusion while maintaining operability. Stem surface roughness must also be adjusted to avoid packing damage.

- Proper Installation of Valve Seals: Proper installation is critical. The installation must strictly follow manufacturer guidelines to ensure the packing is installed correctly, without damage, and each ring receives sufficient sealing stress. Installation personnel must be professionally trained to improve skills and quality awareness.

- Regular Maintenance and Inspection: Even after passing testing, regular maintenance and inspection during use are necessary. Inspect sealing components, replace damaged parts promptly, monitor operation, and prevent decline in sealing performance. Regular maintenance extends valve life, enhances safety and reliability, and reduces environmental risks.

Valve fugitive emission control performance testing and certification are important for ensuring industrial production safety, environmental protection, and production efficiency. Major international standards, such as Europe's ISO 15848-1, the United States'API 624, and Germany's VDI 2440 certification, impose strict requirements on valve sealing performance. By selecting appropriate stem seals, optimizing valve design, ensuring proper installation, and performing regular maintenance and inspection, valves can reliably pass low-leakage type testing and maintain excellent sealing performance in practical applications. In actual production, valve manufacturers and users should attach great importance to testing and certification of fugitive emission control performance, strictly follow relevant standards, and ensure smooth industrial operation and sustainable environmental development.