In modern industry, pipeline systems serve as critical infrastructure for transporting various fluids. Among the many pipeline control devices available, the trunnion mounted ball valve has become a preferred choice for engineers and enterprises alike due to its outstanding performance and broad applicability. This article provides an in-depth discussion of the structure, working principle, advantages, and application scenarios of trunnion mounted ball valves, helping you gain a comprehensive understanding of this high-performance valve.

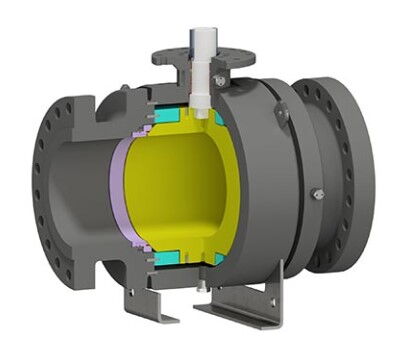

A trunnion mounted ball valve is a high-performance type of ball valve whose core component is a ball supported by two trunnions. The ball features a through-bore equal to the pipeline diameter, with two floating seats positioned on both sides. The rotational center axis of the ball remains stable at all times and does not shift. The key to this design lies in the upper and lower trunnions, which are supported by sliding bearings to ensure stability during rotation.

The valve body consists of a main body, a left sub-body, and a right sub-body. The ball has a journal at the top and a shaft hole at the bottom. A stuffing box is located at the upper part of the valve body, where a sliding bearing connects to the ball journal, while a sliding bearing sleeve is installed inside the shaft hole at the lower end of the ball. The bearing at the bottom of the valve body is inserted into the shaft hole at the lower end of the ball, further fixing its position. This structure ensures that the ball always remains centered during rotation without any displacement.

Two floating seat assemblies are symmetrically arranged on both sides of the ball. Each seat assembly consists of a metal seat ring, a PTFE sealing ring embedded in the seat ring, a rubber O-ring on the outer edge, and a spring at the back. When the valve is closed, the medium pressure acts on the seat assembly, pressing the seat tightly against the ball and generating contact stress to achieve reliable sealing. Sealing between the valve stem and the stuffing box is ensured by rubber O-rings, guaranteeing the overall sealing performance of the valve.

The working principle of the trunnion mounted ball valve is relatively simple yet highly efficient. The valve requires only a 90° rotation to move from fully open to fully closed, or vice versa. This design enables fast and convenient operation, greatly improving efficiency.

Unlike floating ball valves, in trunnion mounted ball valves the medium pressure pushes the seat assembly against the ball to generate the contact stress required for sealing. Since the medium force acts on an annular area, the resulting thrust is much smaller than that in floating ball valves, where the force acts on the entire bore area. This structure makes trunnion mounted ball valves particularly suitable for high-pressure and large-diameter applications, with applicable pressure ratings from Class 150 to Class 2500 and nominal sizes from NPS 2 to NPS 60.

During design, when polymer materials such as PTFE, reinforced PTFE, nylon, or PEEK are used as sealing rings, it is necessary to ensure that the sealing specific pressure q is greater than the required sealing pressure q₍b₎ and less than the allowable pressure of the material [q], that is, q₍b₎ ≤ q ≤ [q]. This requirement ensures reliable sealing performance under various operating conditions.

After understanding the basic structure and working principle, we can further explore the unique advantages that allow trunnion mounted ball valves to stand out among various valve types and make them an ideal choice for industrial fluid control.

One of the greatest advantages of the trunnion mounted ball valve is its excellent sealing performance. Because the combined dimensions of the ball and seat form a free dimension rather than a closed tolerance chain as in floating ball valves, sealing performance is structurally unaffected by temperature or pressure fluctuations. This means that even under extreme operating conditions, stable sealing performance can be maintained.

In addition, the medium force acting on the annular seat area is much smaller than the force acting on the full bore area in floating ball valves. Through proper design, this medium force can be effectively controlled to achieve more reliable sealing. As a result, trunnion mounted ball valves are suitable for all ball valve sizes up to NPS 60 and pressure classes up to Class 2500, making them an important structural form in the development of ball valves.

Because the force generated by upstream fluid pressure is fully transmitted to the bearings rather than causing the ball to move against the seat, trunnion mounted ball valves require relatively low operating torque. Compared with floating ball valves, significantly less torque is needed, making operation easier and reducing operator workload.

The valve seats in trunnion mounted ball valves are not subjected to excessive pressure, resulting in minimal deformation. This not only ensures more stable sealing performance but also significantly extends the service life of the valve. Even under frequent operation, the valve maintains good performance, reducing maintenance and replacement frequency.

Trunnion mounted ball valves offer bi-directional sealing, with two seats in each valve capable of sealing in either flow direction. This eliminates concerns about flow direction during installation and greatly enhances installation flexibility. Bi-directional sealing allows the valve to perform reliably under complex operating conditions.

There are two main body structures for trunnion mounted ball valves: two-piece and three-piece designs. The two-piece design is simple and easy to install, while the three-piece design divides the body into three sections at the seat locations, creating a left-right symmetrical structure. This not only improves valve stability but also facilitates maintenance and inspection.

Trunnion mounted ball valves are suitable for a wide range of media, including steam, gas, oil, weak acids and alkalis, and strongly corrosive media. Their design accounts for strength and resistance to harsh environments, allowing them to handle both corrosive and non-corrosive fluids. This broad applicability has led to widespread use in industries such as industrial chemicals, energy extraction, and natural resource development.

- Industrial Chemical Industry: In industrial chemical applications, trunnion mounted ball valves are widely used to handle various corrosive media. High-temperature- and wear-resistant materials such as PPL are used as sealing components, enabling operation under elevated temperatures. The valve's automatic compensation function effectively addresses gaps caused by sealing surface wear, ensuring long-term stable sealing performance.

- Energy Extraction Industry: In energy extraction, trunnion mounted ball valves are suitable for long-distance transmission pipelines and general industrial pipelines. Their high strength and resistance to harsh environments allow them to withstand high pressures and large diameters. Bi-directional sealing and low operating torque make them particularly effective in oil and gas transmission pipelines, significantly improving efficiency and safety.

- Natural Resource Development: In natural resource development, trunnion mounted ball valves are used in pipelines transporting fluids containing hydrogen sulfide, high impurity levels, and severe corrosive properties. Advanced spring-loaded seat assemblies and fire-safe designs ensure reliable performance under harsh conditions. In addition, low-friction bearing designs and anti-static grounding devices further enhance their value in natural resource applications.

To ensure long-term stable operation, regular maintenance and care are essential. The following are basic maintenance recommendations:

- Regularly check sealing performance: Ensure there is no leakage. Replace seals or repair the valve promptly if leakage is detected.

- Cleaning and lubrication: Clean the valve exterior and interior regularly to remove debris and contaminants, and lubricate moving parts to reduce wear and extend service life.

- Inspect seat-to-ball contact: Ensure contact stress remains within normal limits. Adjust or replace components if abnormalities are found.

- Check stem and stuffing box sealing: Replace O-rings or apply other sealing measures if leakage occurs.

- Inspect valve body strength: Ensure the valve body can withstand current operating conditions, and replace it if damage or deformation is detected.

As a high-performance ball valve, the trunnion mounted ball valve is widely used in modern industry thanks to its excellent sealing performance, low operating torque, long service life, bi-directional sealing capability, multiple body structures, and wide applicability. Whether in industrial chemical processing, energy extraction, or natural resource development, it meets the demands of complex operating conditions and provides reliable solutions for industrial fluid control.

When selecting a trunnion mounted ball valve, users should choose appropriate models and specifications based on specific operating conditions and requirements. Regular maintenance and proper care are also critical to ensuring long-term stable operation. With proper selection and scientific maintenance, trunnion mounted ball valves will provide efficient and reliable support for industrial production.

The development history of trunnion mounted ball valves demonstrates their outstanding position in the industrial valve field. As technology continues to advance and innovate, their performance will further improve and their application range will continue to expand. In the future, trunnion mounted ball valves will play an increasingly important role in more industries, contributing even more to industrial development.