In the industrial sector, valves are critical devices for controlling fluid flow, and their sealing performance is directly linked to operational safety, reliability, and efficiency. Valve sealing systems can generally be divided into two categories: external sealing between the valve body and the bonnet, and internal sealing between various internal components of the valve. External sealing, in particular, can be further classified into forced sealing and pressure seal designs.

This article provides an in-depth analysis of these two sealing methods, examining their working principles, structural characteristics, advantages, application scenarios, and performance under different industrial conditions. By doing so, it aims to help readers gain a deeper understanding of the essence of valve sealing technology and make more informed decisions in practical applications.

Forced sealing is a sealing method achieved through the application of an external mechanical force. The most common example is tightening bonnet bolts to compress a gasket, thereby generating sealing pressure. When the gasket is compressed, the microscopic irregularities on the sealing surfaces are filled, creating initial sealing conditions, commonly referred to as preload sealing contact stress. This preload stress is the fundamental factor that prevents medium leakage.

During valve operation, as internal pressure increases and the valve undergoes repeated opening and closing cycles, the preload sealing stress on the sealing surfaces gradually decreases, and the gasket tends to rebound. If the gasket has sufficient resilience to ensure that the working sealing contact stress remains greater than the combined effect of medium pressure and operational forces, effective sealing can be maintained.

A key prerequisite for forced sealing is that, even under medium pressure, a certain residual compressive force must remain on the sealing surfaces. This is because the internal pressure of the medium inherently acts to reduce the preload sealing stress, thereby weakening the sealing performance.

Typical forced sealing structures include flat gasket seals, spiral wound gasket seals, and metal serrated gasket seals. These designs are commonly used for bonnet sealing in medium- and low-pressure valves as well as small- to medium-diameter valves.

Ball valves, medium- and low-pressure cast steel gate valves, and other cast steel valves frequently adopt these sealing structures. Their simple design, ease of installation, and reliable performance make them well suited for general industrial service conditions.

Forced sealing is widely applied in industries such as petrochemicals, natural gas, and aerospace. In these fields, valves often operate under medium to low pressure and within moderate size ranges, where forced sealing provides dependable sealing performance.

For example, in natural gas transmission pipelines, medium- and low-pressure ball valves equipped with forced sealing structures can effectively prevent gas leakage, ensuring pipeline safety and stable operation.

Pressure seal technology utilizes the pressure of the working medium itself to enhance sealing performance and is typically applied in high-temperature, high-pressure, and large-diameter valves. The defining feature of pressure seal designs is that the higher the medium pressure, the better the sealing performance. A classic example of this design is the wedge-type gasket pressure seal structure.

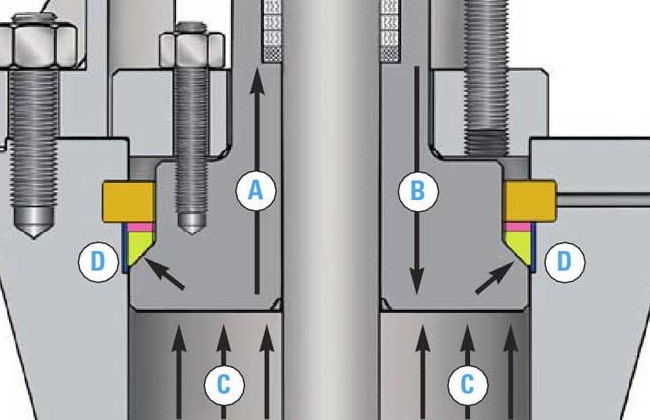

Before pressurization, the preload bolts are tightened to lift the valve bonnet, forming initial sealing conditions between the bonnet and the wedge-shaped gasket, as well as between the gasket and the valve body. This creates the initial preload sealing contact stress.

As the medium pressure rises, the bonnet is subjected to upward force, causing it to move slightly upward. This movement increases the sealing contact stress between the bonnet and the wedge gasket, and between the valve body and the wedge gasket. In pressure seal designs, the working sealing stress is composed of two parts:

- The initial preload sealing stress

- The additional sealing stress generated by medium pressure

As a result, the medium pressure actively contributes to increasing the sealing force, rather than reducing it, thereby significantly enhancing sealing reliability.

The most notable characteristic of pressure seals is that sealing performance improves as medium pressure increases. This makes pressure seal designs particularly suitable for high-temperature and high-pressure service conditions.

In refinery units such as hydrocracking, hydrotreating, and residue hydrodesulfurization, globe valves commonly adopt pressure seal bonnets. To ensure reliable sealing performance under elevated temperatures, the sealing surfaces between the valve body, bonnet, and wedge gasket are often overlay welded with austenitic stainless steel or hard-facing alloys.

The overlay thickness is typically around 2 mm, serving to:

- Increase surface hardness

- Improve corrosion and erosion resistance

- Enhance sealing surface durability

This overlay also creates favorable contact geometry and angle differentials with the wedge gasket, further improving sealing effectiveness.

Pressure seals are widely used in demanding industries such as petrochemicals, natural gas, aerospace, and nuclear power. In these applications, valves must operate reliably under extreme conditions involving high pressure, high temperature, and large diameters.

For instance, in nuclear power plant cooling systems, high-pressure globe valves equipped with pressure seal bonnets can effectively prevent coolant leakage, ensuring safe and stable plant operation.

Pressure-sealed valves represent a specialized category of valves that rely on medium pressure acting on specific sealing elements, such as wedge discs, pistons, or bellows, to induce elastic or plastic deformation. This deformation causes the sealing elements to press more tightly against the sealing surfaces, forming an increasingly effective seal.

The higher the medium pressure, the greater the compressive force on the sealing surfaces, and the better the sealing performance.

The bonnet structure of a pressure-sealed valve typically consists of the bonnet, support ring, retaining ring, and sealing gasket. After installation, a preload force is applied to the connection, lifting the bonnet and generating initial compressive force between the bonnet and the gasket, as well as between the gasket and the valve body.

Once the system is commissioned and the internal pressure rises, the force acting on the bonnet increases, causing it to move upward slightly. This movement further increases the sealing contact stress between all mating surfaces. As with other pressure seal designs, higher medium pressure results in higher working sealing stress and improved sealing performance.

Pressure-sealed valves are extensively used in industries with stringent safety and reliability requirements, including petrochemicals, natural gas, aerospace, and nuclear power.

They are particularly advantageous in special service conditions such as:

- Long-distance, low-pressure pipelines requiring enhanced leak prevention

- Control of toxic, flammable, or hazardous media

Due to their structural characteristics and sealing mechanism, pressure-sealed valves perform exceptionally well under high-temperature and high-pressure conditions. They are especially suitable for high-pressure globe valves, high-temperature globe valves, high-pressure welded globe valves, and large-diameter valves.

After examining the fundamental principles and applications of forced sealing and pressure seal designs, it is important to analyze how these sealing concepts are implemented in various valve types. Each valve type has its own structural characteristics and operating principles, which determine its specific sealing method and suitability for different service conditions.

Below is an overview of sealing methods used in common valve types, including gate valves, ball valves, butterfly valves, globe valves, and check valves.

Gate valves are widely used shutoff valves in which a gate disc moves vertically to block the flow passage. Parallel gate valves typically use forced flat-face sealing, while wedge gate valves rely on the wedge angle to generate a self-sealing effect during closure.

This design allows gate valves to provide reliable sealing under medium to low pressure and small to medium diameter conditions, making them common in petrochemical and natural gas applications.

Ball valves control flow through the rotation of a spherical closure element. In the closed position, medium pressure pushes the ball slightly downstream, forcing it tightly against the rear seat to form a reliable seal.

Soft-seated ball valves, in particular, offer excellent sealing performance and are well suited for applications requiring tight shutoff. The self-sealing nature of ball valves enables them to maintain good sealing performance even under high-pressure and large-diameter conditions.

Most butterfly valves feature an eccentric design. When the disc rotates to the closed position, a cam-like action causes the sealing ring to interfere with the valve seat, generating both forced sealing and self-sealing effects.

This combined mechanism allows butterfly valves to achieve reliable sealing under medium to low pressure and moderate size conditions, especially in applications requiring frequent operation, such as pipeline systems in the petrochemical and natural gas industries.

Globe valves achieve sealing by driving the disc vertically onto the seat through the valve stem. The flow direction is typically arranged so that the medium assists disc closure during shutoff, enhancing sealing effectiveness.

The forced sealing structure of globe valves provides dependable performance in medium to low pressure and small to medium diameter applications and is widely used in petrochemical and natural gas systems.

Check valves rely entirely on the flow energy of the medium for operation. Forward flow opens the valve, while reverse flow forces the disc or closure element back onto the seat, automatically forming a seal.

This self-sealing mechanism makes check valves highly reliable for preventing reverse flow in pipeline systems, particularly in petrochemical and natural gas applications operating under medium to low pressure conditions.

Valve sealing technology is an indispensable component of modern industrial systems. Forced sealing and pressure seal designs represent two fundamental sealing philosophies, each with distinct principles, characteristics, and application ranges.

Forced sealing relies on external mechanical force and is best suited for medium- and low-pressure, small- to medium-diameter valves. Pressure seal designs, on the other hand, utilize the pressure of the working medium itself and are ideally suited for high-temperature, high-pressure, and large-diameter valves. Pressure-sealed valves, as a specialized form, deliver outstanding performance under demanding and hazardous service conditions.

In practical applications, selecting the appropriate sealing method and valve type requires a comprehensive evaluation of medium properties, pressure, temperature, and valve size. By thoroughly understanding the principles of forced sealing and pressure seal designs, as well as the sealing characteristics of different valve types, engineers and operators can make informed decisions that ensure safe, efficient, and reliable industrial operation.